Quality control application

Tracking application for all product details during manufacturing in order to reduce the possibility of bad quality

Improving quality control

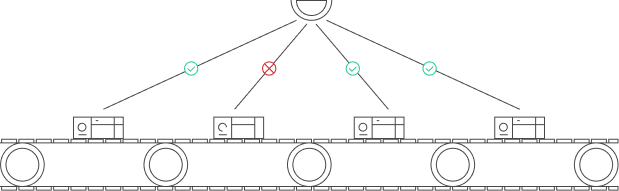

Quality control application for automotive manufacturing lines in factories. Tracking products on the line(s) and their status/quality during the manufacturing process in real-time.

Improving quality control

Quality control application for automotive manufacturing lines in factories. Tracking products on the line(s) and their status/quality during the manufacturing process in real-time.

Reducing risk caused by tedious work on manufacturing lines

Within the production process the need for checking the quality of specific pump parts showed up. The client wanted to have stored all specific details about each part in the manufactured pump. General idea was to install a camera on the manufacturing line and by taking specific action take product part details including fresh picture and store it in database. Afterward, it was possible to provide search and sort per different criteria.

Ewasoft succeeded to develop a custom application which was gathering all requested information about each product part and store it. User has the option to search per specific parts, per manufacturing number, etc., and see the picture in order to check the quality of work that is done in the specific case.

Grundfos

Grundfos is a pump manufacturer, based in Denmark, with more than 19 000 employees globally. The annual production amounts to more than 16 million pump units, circulator pumps, submersible pumps, and centrifugal pumps.

The company also produces electric motors for the pumps as well as electric motors for separate merchandising. Grundfos develops and sells electronics for checks in terms of pumps and other system operations.

We delivered a solution for tracking all details for manufactured pumps in real-time.

Their experience working on world-class projects is clearly reflected in their work ethics & quality. They use the best engineering standards in planning & execution and this results in outstanding product quality.